Capabilities

Our Core Capabilities

Embedded IT Solutions (India) Pvt. Ltd., provide services that include new product prototyping with FMEA, simple to high technology PCBA manufacturing capability and build-to-order systems assembly. Our products are manufactured by high-end SMT technology machines to meet global quality standards and are supported by a dedicated after market services and repairs.

WHAT WE DO - Capabilities

We strive to attain a reputation for the best manufacturing practices and quality through continual improvement of our process and products.

NPI / Prototyping

EIS's array of services encompasses contract manufacturing, cutting-edge new product prototyping supported by FMEA analysis, mid-range volume production, PCBA manufacturing with POP capabilities, as well as complete turnkey solutions for build-to-order (BTO) and configure-to-order (CTO) systems assembly.

- Partner from concept to finished product

- Dedicated project manager for each customer

- Prototype experts

- Component specialists

- Design for Excellence

- Test development

We strive to attain a reputation for the best manufacturing practices and quality through continual improvement of our process and products.

PCB Assembly & Box Build Offers:

Manufacturing Capabilities: Our assembly line supports smallest component sizes down to 01005. Our process uses JEDEC guidelines and IPC standards for PCB component placement, soldering, and inspection to maintain quality control.

- Single sided, double sided SMT

- 01005 chip components, BGAs, micro BGAs, CSPs, QFNs

- Single and multi layered boards

- PCB assemblies

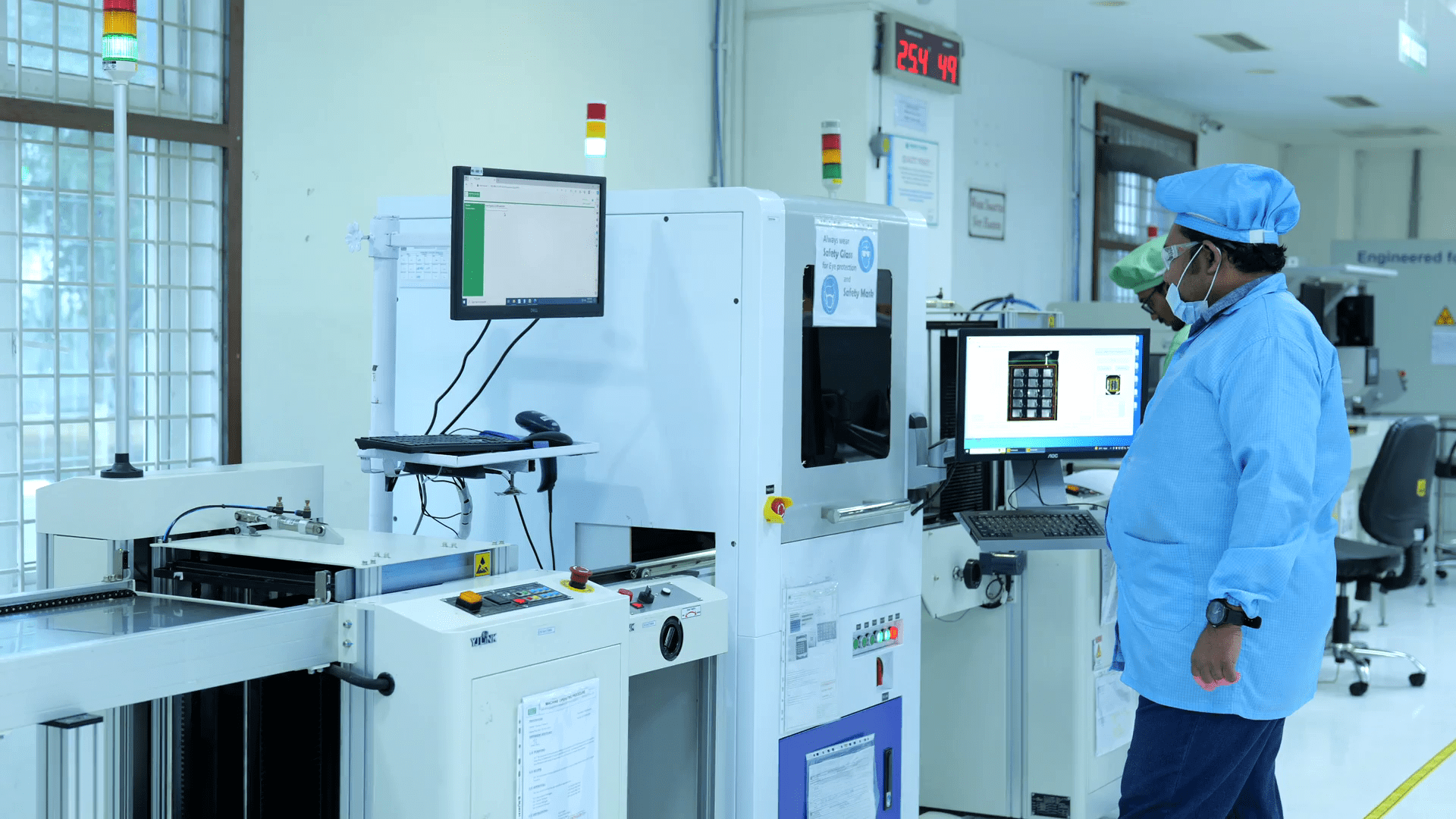

- Automated Optical Inspection(AOI)

- Box build assembly

- System tests on box-build assemblies

We strive to attain a reputation for the best manufacturing practices and quality through continual improvement of our process and products.

Electronic Manufacturing

- Printed circuit board assembly (PCBA)

- Electronic Cable & Harness Assembly Design and Processes

- Box Build Assemblies

- Equipped with surface mount technology (SMT)

- Plated through hole boards (PTH)

- Conformal/Protective coating

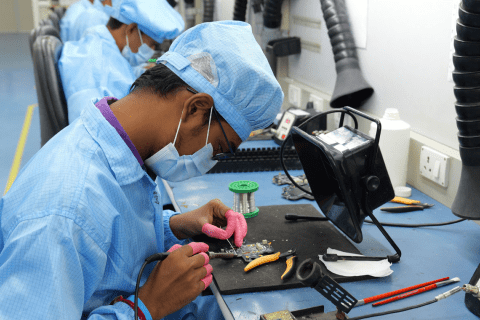

- Robotic and Manual Testing and inspection services

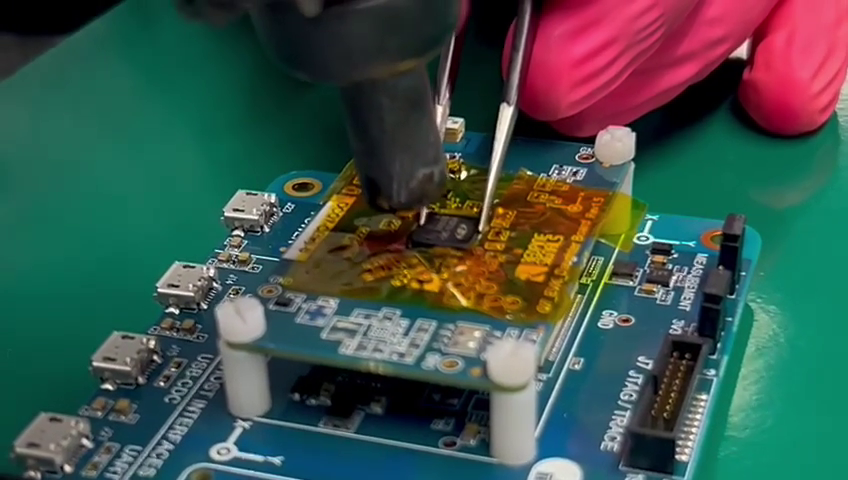

- IPC 7711 Certified Rework Operators.

We strive to attain a reputation for the best manufacturing practices and quality through continual improvement of our process and products.

Product Testing

EIS specializes in crafting test strategies and methods that empower you to manage inventory efficiently, boost profitability, and expedite both time-to-volume and time-to-market for all the products we manufacture.

- Functional Testing

- Structural Testing

- Reliability Testing

- Life Cycle Testing

We strive to attain a reputation for the best manufacturing practices and quality through continual improvement of our process and products.

After Sales & Warranty

We offer after-sales support and warranty services abiding by the contractual obligations with the customers. Our team will be upright in offering any kind of technical and logistics support to the customers.

- RMA (Return Material Authorization) products under warranty

- Coordinating with logistics, defect analysis and rework/repair, retests and dispatching

- Quick turn around time for normal repairs and prior information on repair of other products

- Are you utilizing a testing strategy to maximize the success of your product?

- At any phase in the design and development process, or as part of our electronics manufacturing services, test engineering teams in your business units of choice will work with you to develop a test strategy and select test methods that enable you to reduce inventory bone-piles, increase yields and accelerate time-to-volume for every product we build.

Our Manufacturing lines are equipped as shown below

Laser Marking Machine

Bar codes marking, 2D codes and characters, graphics and other information on any kinds of printed circuit board. Integrated with high-performance

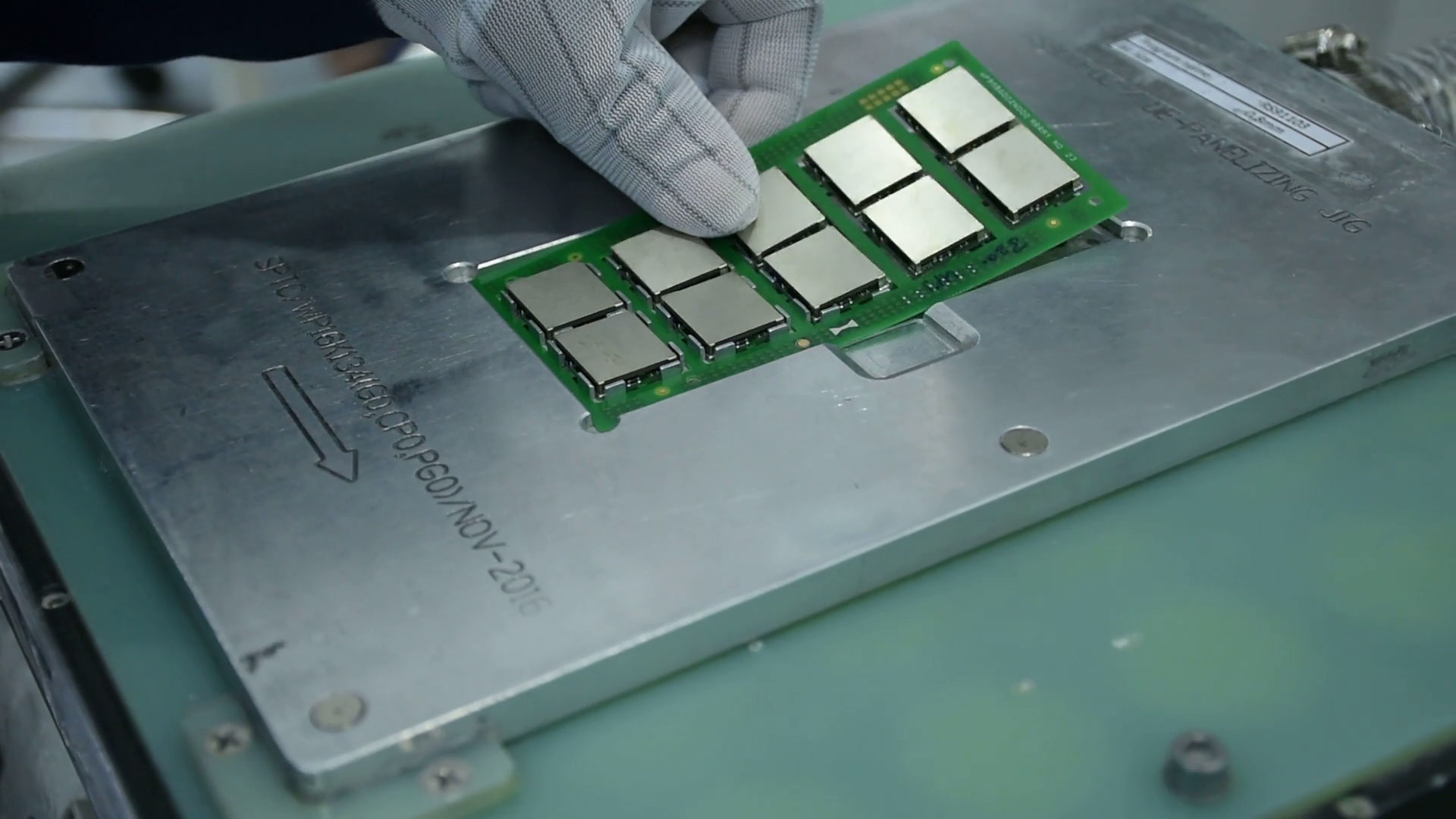

PCB Depaneling Process

Record manufacturing operational activities using Routing M/C

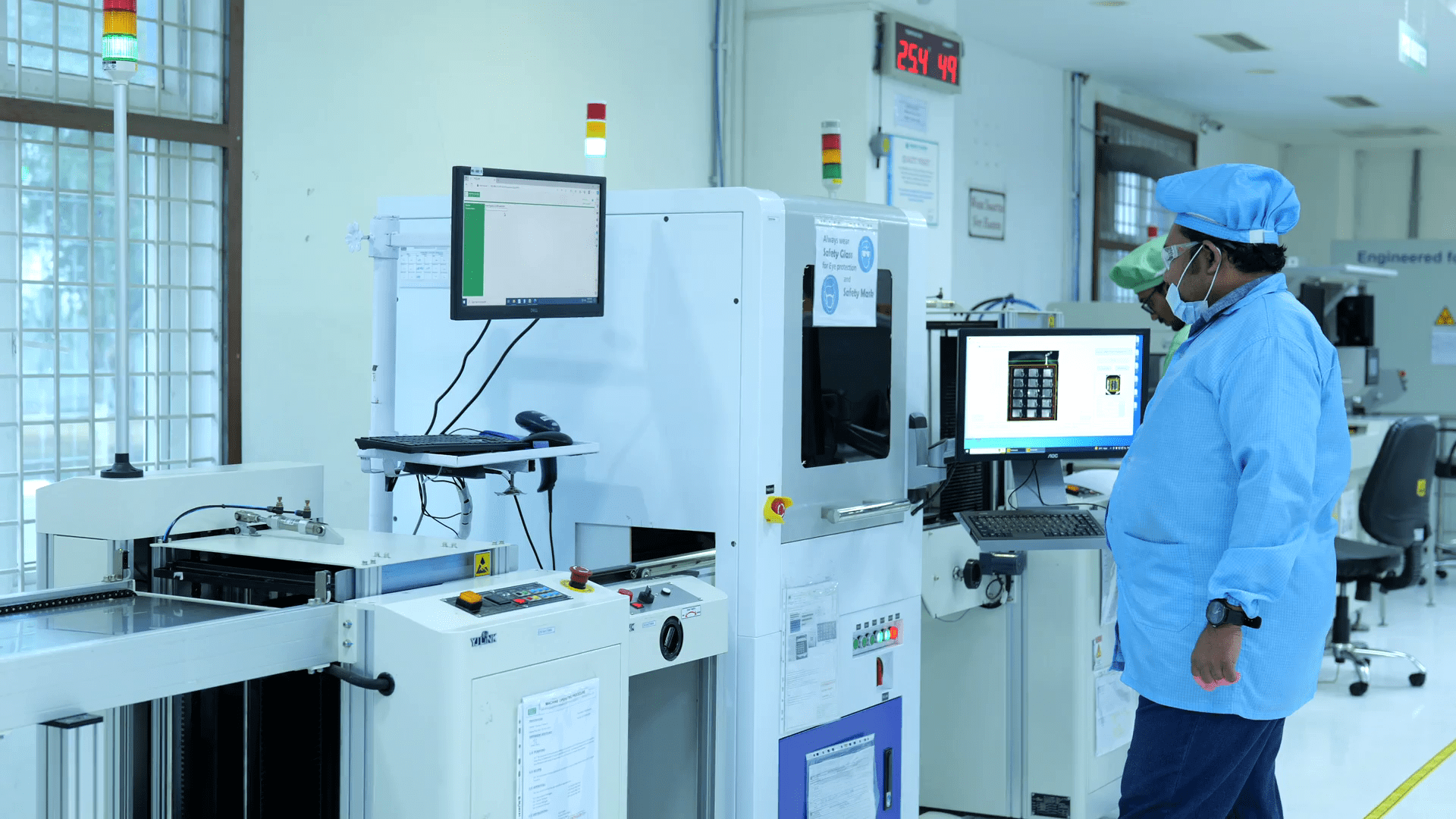

Testing and Inspection

Quality And Reliability. Our Standard Flow Includes Visual Inspection And Automated Optical Inspection, X-Ray, ICT Etc.

Fuji AMEX 3 p-n-p machine

This is an all-in-on machine with scalability and the ultimate level of versatility necessary for increasing productivity for high-mix production

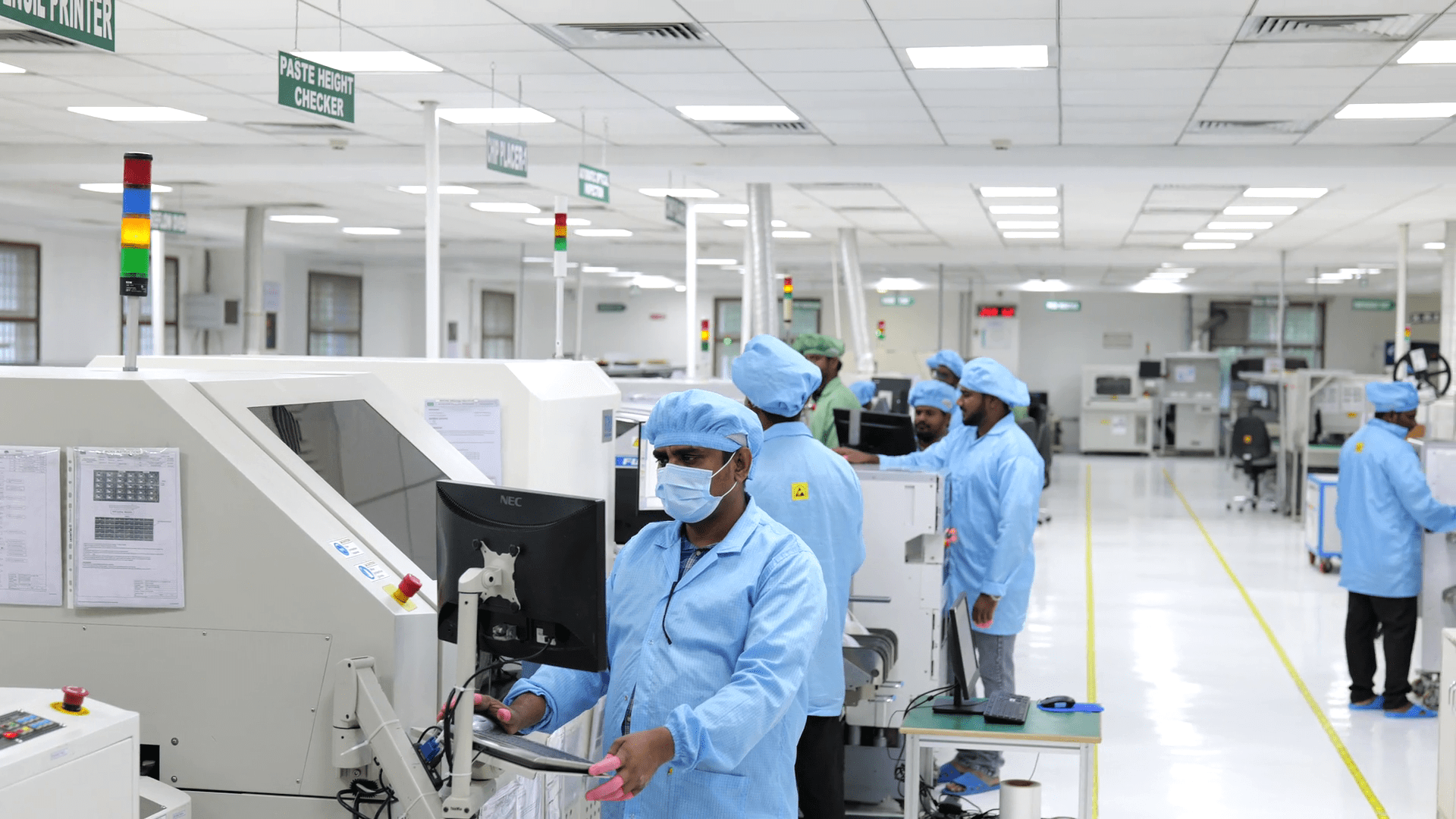

Shopfloor

Our heart of the production process for electronic devices. It involves a combination of technology, human expertise, and systematic processes.

SMT Lines – XP Series

First SMT line XP series with two Chip Shooter and one Precision Placer with a placement speed (throughput) of 50K component per hour (CPH)

Robotic Auto Handler Unit

4 testers in one Unit to Produce 2 M PCB Boards for Testing

SMT Lines – Fuji AIMEX IIIC

Third SMT line with latest Fuji machines (AIMEX III C) with placement Speed of 120K CPH

PCB Rework

Bar codes marking, 2D codes and characters, graphics and other information on any kinds of printed circuit board. Integrated with high-performance

X-Ray

Record manufacturing operational activities using Routing M/C

EMS Fecility 1

Quality And Reliability. Our Standard Flow Includes Visual Inspection And Automated Optical Inspection, X-Ray, ICT Etc.

EMS Fecility 2

This is an all-in-on machine with scalability and the ultimate level of versatility necessary for increasing productivity for high-mix production

Our Features

Our Manufacturing lines are equipped as shown below (to name a few):

- Speedline MPM 125 Screen printer

- GKG – titan Screen printer

- NXT II M3X2 Modules for chip placing and Optional Glue dispensing head

- NXT II M6S with Tray unit for chip & IC/ BGA /other Components mounting

- XP 141E for chip mounting

- XP 142 E for chip mounting

- XP 242E for fine pitch and BGA component mounting

- 3D SPI off -line checking machine

- AIMEX III C with Tray unit for chip & IC/ BGA /other Components mounting

- Speedline Omni ES 10 re-flow machine

- Keli smart-3500 for PCBA De-panelling

- JT WS-450 & WS-350 Wave Soldering machine with a separate pot for lead free processing

- Fiber & UV laser machine for permanent marking on the product

- GIT Automatic tester with integrated MES for IoT product

OUR PRODUCT RANGE

Our boards are being used in sophisticated products catering for various commercial and industrial segments.

Wi-Fi modules Devices

GPS tracking devices

Point-of-sale terminals

Bio-medical devices

LED drivers

Wireless communication systems

Train collision avoidance systems

Smart lighting control systems

UPS and power supply solutions

Smart Home Appliances

CERTIFICATIONS & COMPLIANCES

Our Recognition & Awards

Certified for ISO 9001:2015 Quality Management Systems

Certified for IATF 16949:2016 International Automotive Task Force

Compliance with ANSI / ESD 520.20-2021 Requirements Standards

Certified for Responsible Business Alliance

Certified for 14001:2015 Environmental Management Systems

Certified for 45001:2018 health and safety Systems

Certified for ISO / IEC 27002-2013

Our Gallery

Future Ready Infrastructure and State Of The Art Facilities.

Advantages

Special Economic Zone (SEZ) Location

- Embedded IT Solutions (EIS) is located in Fabcity - Special Economic Zone (SEZ) a duty free zone for export and import, near Hyderabad International Airport

- The plant has been setup in a 10 acre campus with an initial manufacturing floor area of 50,000 sq. ft. built with green building concepts

- SEZ on filing on BOE, Shipping Bill (Export), DTA procurement, DTA Sales and Sub-contracting clearance on daily basis due to presence of customer officer

OUR CLIENTS

Growth Enablers

International Customer Base

Domestic Customer Base